Fig.1. Photo of a power transformer with the Series transformer - circled in green

AMforum Journal 1

Transformers equipped with a series transformer - or a booster transformer, to minimize the current OLTC switches during the tap changing process are explained in this document.

DEFINITION : Series transformer

In certain parts of the world, OLTC is located in the low voltage (Secondary) winding of a power transformer, like the USA, while the other parts of the world put the OLTC in the HV winding, typically in Europe.

Since the current of the LV winding is higher than the HV winding current, OLTCs located in the LV windings have to switch higher currents. To lower this current, a series transformer is introduced.

The Waukesha Electric System (WES) states:

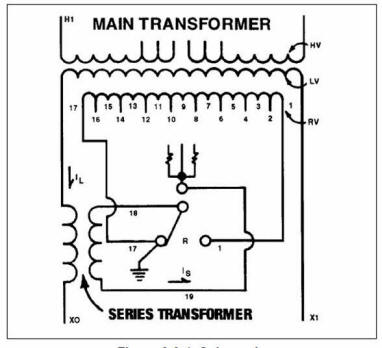

Here is a portion of the nameplate showing this arrangement. It is clear that there is no electrical contact between the secondary winding (LV) and the regulating winding (RV) connected to the tap changer. The only coupling is magnetically through the series transformer.

Fig.2. Portion of the transformer nameplate showing series transformer

TESTING

Testing DRM presents a special case and requires a special procedure. One is developed following a proprietary algorithm patented by DV Power.

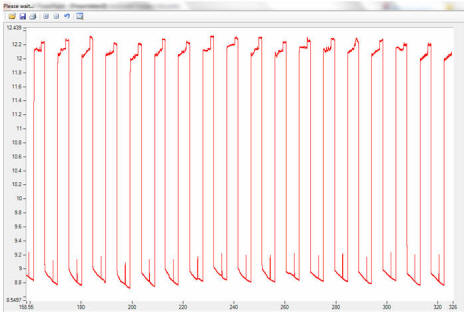

Dynamic Resistance Measurement is a winding resistance test current record during a tap change. Having this in mind, lets discuss the winding resistance results. This is also known as a "static resistance" or the Winding resistance results of the secondary winding does not change as a tap position is being changed. This can be deduced visually observing the schematic diagram of the nameplate, as no tap changer nor the regulating winding are in the test circuit. To conclude - a graph of the static resistance results for each tap position, should be a flat horizontal line.

Likewise, the DRM graph should also be a flat diagram as shown on the figure below, because there is no resistance change.

Fig.3. A flat DRM graph

Knowing all this, the analysis of the tap changer transition is based on the ripple evaluation only. To see the ripple we need to excite the series transformer winding in order to reflect the ripple of its current on the current we measure - the test current through the secondary. We have devised the procedure where a disturbance is introduced in the circuit by sharply changing the test current. This change induces the voltage and current in the regulating winding, since during the DC test there is no current in other windings.

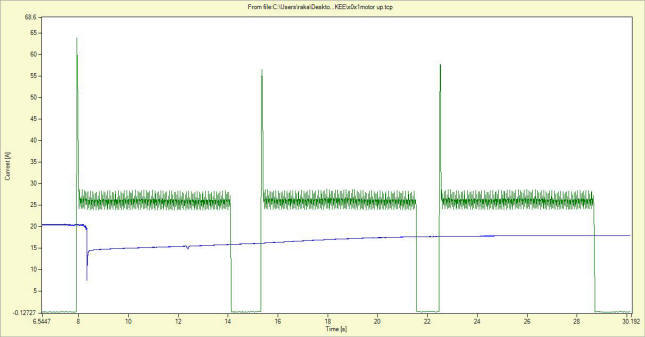

The graph below shows three motor operations (green trace), i.e. three tap changing operations. As the excitation disturbance is introduced immediately after the motor starts for the first time, the reflection of the ripple during the first transition is visible, while the other two are not.

Fig.4. Three tap changing operations - only the first one shows the reflection

of the ripple

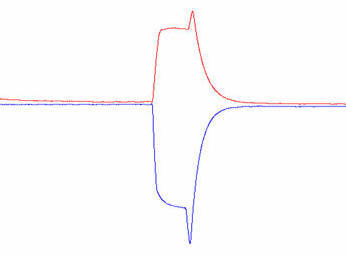

This reflection is the mirror image in the opposite direction, i.e. a normal ripple may be a current drop, now the ripple becomes a current "jump".

Fig.5. Ripple in blue, and reflection trace in red.

ANALYSIS

The analysis of the DRM graph can be performed by checking transition times of each tap changing operation. The transition time comprises of three segments resistor 1 in the circuit, resistors 1 and 2 in the circuit, and the last one resistor 2 in the circuit, before the main contacts make, as observed on the DRM graph as an exponential raise, where the current goes into recovery.

Any discrepancy in the ripple value may indicate a potential problem. However, we have seen that the ripple changes from tap to tap position, or even changes its direction (we will write about this in the next issue of Journal) and depending on the parameters of the test circuit may hinder this evaluation.

Contributor

Dr.ing. Raka Levi